The Role of Automated Test Equipment (ATE) in Semiconductor Testing

In the fast-evolving world of semiconductor manufacturing, Automated Test Equipment (ATE) plays a crucial role in ensuring that integrated circuits (ICs) meet performance standards before they are packaged and shipped. ATE systems are designed to streamline the testing process, improving efficiency, accuracy, and scalability. This blog will delve into how ATE systems function, their importance in semiconductor testing, and the benefits they provide.

What is Automated Test Equipment (ATE)?

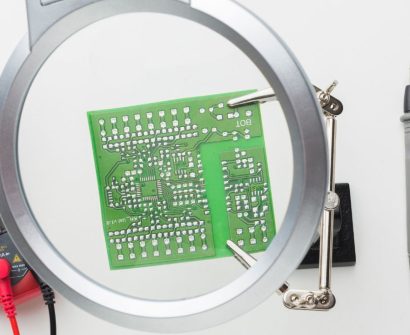

Automated Test Equipment (ATE) is a machine that tests ICs, printed circuit boards (PCBs), and other electronic components during the manufacturing process. The goal is to verify that the components are functioning correctly, meeting design specifications, and performing reliably under different conditions.

ATE systems are capable of executing a wide range of tests, such as:

- Functional Testing – Verifying that the component operates according to its design.

- Parametric Testing – Measuring specific electrical characteristics like voltage, current, and resistance.

- Stress Testing – Checking the component’s performance under varying environmental conditions (temperature, humidity, etc.).

Importance of ATE in Semiconductor Testing

With increasing complexity in IC design and the growing demand for faster time-to-market, manual testing has become impractical. This is where ATE systems shine. They can perform multiple tests at different stages of the semiconductor production process, from wafer testing to packaged device testing, ensuring quality and reliability.

Here are some key reasons why ATE systems are indispensable in semiconductor testing:

- Efficiency and Speed

ATE systems dramatically reduce the time it takes to test a batch of ICs. By automating the testing process, manufacturers can scale up production while maintaining accuracy, reducing the overall testing cycle time. - Precision and Accuracy

Semiconductor devices operate in extremely precise conditions. ATE systems offer the ability to measure with a high degree of accuracy, catching even the smallest of defects that manual testing might miss. - Cost-Effective Testing

Though ATE systems require a significant initial investment, the long-term cost savings are substantial. Automating the testing process reduces labor costs and minimizes human error, improving yield rates and reducing waste. - Scalability

ATE can be scaled to test a wide variety of semiconductor devices, from simple analog ICs to complex system-on-chips (SoCs). This versatility makes it a vital tool for manufacturers producing a broad range of electronic components. - Testing in Mass Production

In mass production environments, it is crucial to maintain consistent quality across thousands or even millions of units. ATE systems allow manufacturers to test each unit with uniform criteria, ensuring that every device that leaves the factory is reliable.

How ATE Systems Work

An ATE system consists of a test head, handler, and prober. Here’s how they work together to test semiconductor devices efficiently:

- Test Head

The test head contains various instruments and interfaces required to apply stimulus signals to the device under test (DUT). It measures responses from the DUT and compares them to expected results. - Handler

The handler is responsible for positioning the DUT in the test head and managing its movement through the testing process. For example, during wafer-level testing, a prober may handle the wafer, ensuring that each die is tested before being cut from the wafer. - Prober

The prober connects the ATE to the wafer for wafer testing. It uses tiny needles or probes to contact the semiconductor device’s pads or pins, allowing the ATE to measure the electrical characteristics of each individual die.

Once the DUT has been tested, the ATE system can either reject it if it fails the tests or pass it to the next stage of the manufacturing process if it meets the required performance specifications.

Benefits of ATE in Semiconductor Manufacturing

- Increased Throughput

By automating the entire testing process, ATE systems allow manufacturers to test hundreds or even thousands of devices simultaneously, significantly increasing throughput. - Data Collection and Analysis

ATE systems not only perform tests but also collect vast amounts of data on the performance of each device. This data can be used to improve future designs, optimize manufacturing processes, and reduce failure rates. - Consistency in Testing

ATE systems follow standardized protocols, ensuring that every device is tested under the same conditions. This uniformity helps maintain product quality and consistency, which is especially important for critical applications such as automotive and medical electronics. - Reduction in Time-to-Market

Faster, more efficient testing means products can move through the manufacturing process quicker, helping companies meet market demands and reduce time-to-market. - Flexibility in Testing Multiple Devices

ATE systems can be reconfigured to test different types of semiconductor devices. This flexibility is crucial in today’s rapidly changing semiconductor landscape, where manufacturers may need to switch production lines quickly.

Conclusion

Automated Test Equipment (ATE) plays a pivotal role in the semiconductor industry, providing a reliable, scalable, and cost-effective solution for testing integrated circuits. As IC designs grow increasingly complex, the need for accurate and efficient testing becomes even more critical. ATE systems not only enhance the speed and precision of semiconductor testing but also contribute significantly to improving product quality and ensuring that electronic devices function as expected. By adopting ATE systems, semiconductor manufacturers can boost efficiency, reduce costs, and maintain a competitive edge in the fast-paced electronics market.

By following this structure and incorporating relevant keywords like “Automated Test Equipment,” “semiconductor testing,” “ATE systems,” and “integrated circuits,” this blog post aligns with Yoast SEO guidelines, ensuring high search engine visibility and a readability score suitable for a broad audience.